Closed-Loop Control of Weaving Machine using the Cogent DatHub

RWTH Aachen University - Germany Case Study

From ancient times people have been using looms to weave cloth, canvas, and carpets. As the centuries passed, weaving became one of the first tasks to be mechanized in the industrial revolution. The various repetitive tasks such as raising and lowering rows of threads (the warp), and passing a shuttle with the cross-thread (the weft) back and forth between them, were a good fit for simple machines. Today, high-speed air-jet weaving machines are fully automated, and capable of sending a warp thread between weft strands at a rate of 2000 times per minute.

One of the challenges of automating a weaving machine is maintaining proper tension on the threads. With each pass of the weft, a certain amount of tautness must be applied to the warp to keep the woven fabric uniform at all times. Early looms used the weaver's body weight or hanging stones to keep the warp taut, but an air-jet machine needs a more sophisticated technology.

This challenge has been addressed by the students and faculty of the Institut für Textiltechnik (ITA) der RWTH Aachen University in Aachen, Germany, who are investigating how to optimize the tension of warp threads in an air-jet weaving machine.

This challenge has been addressed by the students and faculty of the Institut für Textiltechnik (ITA) der RWTH Aachen University in Aachen, Germany, who are investigating how to optimize the tension of warp threads in an air-jet weaving machine.

"Our main research goal is self-optimization of the warp tension," said Dr. Ing. Yves-Simon Gloy, Research Manager at ITA, "to enable the loom to set the warp tension automatically at a minimum level without reducing the process stability." Keeping the proper tension maximizes the speed of the process, while yielding the highest possible quality of fabric.

"We started by creating an automated sequence routine, with the help of regression models for a model-based setting of the loom, and implemented in the weaving process," said Dr. Gloy. "The automated sequence routine was implemented using the ibaPADU-S-IT as a fast, stand-alone control system and the software ibalogic from iba AG in Fürth, Germany."

"We started by creating an automated sequence routine, with the help of regression models for a model-based setting of the loom, and implemented in the weaving process," said Dr. Gloy. "The automated sequence routine was implemented using the ibaPADU-S-IT as a fast, stand-alone control system and the software ibalogic from iba AG in Fürth, Germany."

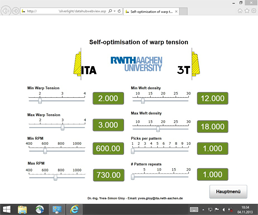

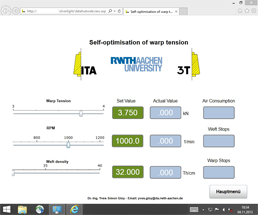

Once the necessary hardware was in place, the team needed to choose a way to monitor and control the loom, Cogent DataHub® seems like the ideal solution. Connecting the Cogent DataHub to the iba System OPC server, Dr. Gloy and his team were able to use DataHub WebView™ to quickly build a web HMI.

Once the necessary hardware was in place, the team needed to choose a way to monitor and control the loom, Cogent DataHub® seems like the ideal solution. Connecting the Cogent DataHub to the iba System OPC server, Dr. Gloy and his team were able to use DataHub WebView™ to quickly build a web HMI.

"The Cogent DataHub was the perfect tool to develop the new HMI – easy to install, easy to handle. I got very fast results and the control of the loom via the web browsers is totally stable," said Dr. Gloy. "Our students are very impressed by the Cogent DataHub and its functionality. We can even view the HMI on a tablet, which is beyond state-of-the-art for a textile machine. Now we are investigating new applications for other textile machines in our Institute."

OPC DataHub is a trademark of Cogent Real Time Systems. Software Toolbox is a trademark of Software Toolbox, Inc.

Try It Yourself - How-To Video and DataHub Free Trial

STAY CONNECTED

1-888-665-3678 (US + Canada)

+1-704-849-2773 (Global)

+1-704-849-6388 (Fax)

support.softwaretoolbox.com

WORKING WITH US

WHO WE ARE

RECENT POSTS

Usage subject to our website terms and conditions.